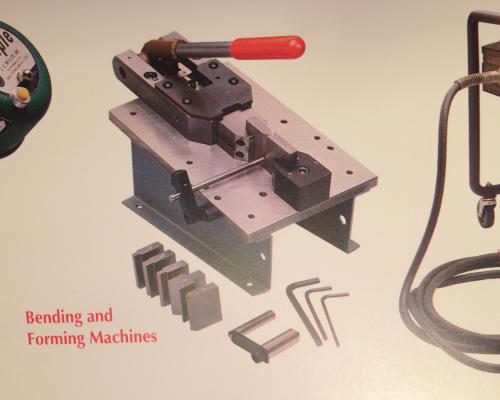

The Mighty Midget

Bending & Forming Machine by J.E.Miller, Inc.

From prototype to medium run production, the Mighty Midget will give you the competitive edge. The possibilities are endless!

PRECISE BENDS

QUICK SETUP

QUALITY YOU CAN RELY ON!

Each component is designed to provide years of dependable service. The exclusive toggle action and micro adjustment assures precise bends every time. All models feature hardened and ground tables, rams, and die holders.

The Model 70 offers high speed pneumatic operation. It comes complete with safety interlock, for manual operation, and standard tooling.

Bend Capacity

- Model 60/70: 1/8” x 1” or 1/4” dia. steel

- Model 30: 1/16” x 1/2” or 1/8” dia. steel

Weight

- Model 30: 5.5 lbs. net, 6.5 lbs. shipping

- Model 60: 45.0 lbs. net, 50.0 lbs. shipping

- Model 70: 55.0 lbs. net, 60.0 lbs. shipping

Model 70The Model 70 offers high speed pneumatic operation. It comes complete with safety interlock, for manual operation, and standard tooling as shown. PA-100 Punching Attachment for holesModel PA-100 punching attachment turns your model 60 or 70 into a versatile hole punch. RT-100 Radius Tool for smoother bending & formingModel RT-100 radius tool attachment eliminates marring and digs that spoil soft metal or plated surfaces and require polishing. Hardened steel rollers rotate with the stock providing a friction free band. Rollers are adjustable from a friction free bend. Rollers are adjustable from a 3/8” to a 2 1/4” wide gap, and dies are provided for 1/16”, 1/8”, and 3/16” radius bends. other die sizes available upon request. |

Features and Specs

Custom ToolingTo meet your special applications, we will design and build custom tooling. Ask for details! |

CALL US AT 1-800-298-0452

FOR A QUOTE

We’re your partner in engineering and design problem solving. Please call or fax so we can discuss your specific requirements.